LOPO’s Advanced Terracotta Manufacturing: A Commitment to Quality and Efficiency

LOPO’s Advanced Terracotta Manufacturing – LOPO Terracotta Corporation is dedicated to excellence in both sourcing and technology. From the meticulous selection of raw materials to each step of the production process, LOPO ensures that every terracotta panel and tile meets the highest quality standards. This attention to detail guarantees that every product delivers superior durability, aesthetics, and performance.

State-of-the-Art Production Facilities

LOPO boasts world-class production lines and cutting-edge equipment, some of which is imported from Italy, while others are custom-built locally. The company’s impressive annual production capacity includes:

- 4.5 million square meters of Clay Tiles

- 1.5 million square meters of Terracotta Facade Panels

- 600,000 square meters of Cultured Stone

These production capabilities are supported by highly efficient energy management systems, ensuring that every product is made sustainably, with minimal energy consumption.

Key Features of LOPO’s Production Line

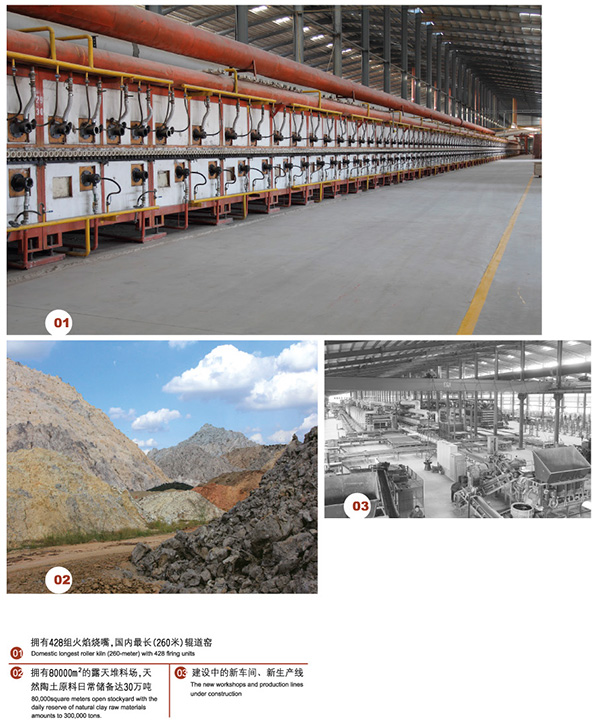

- Raw Material Reserves:

- 80,000 square meters of open-air stockyards with 300,000 tons of natural clay reserves.

- 150,000 tons of indoor storage capacity for raw materials.

- 12,000 tons of storage capacity for mud materials.

These extensive reserves ensure consistent product quality and allow LOPO to fulfill large-volume orders with quick delivery times.

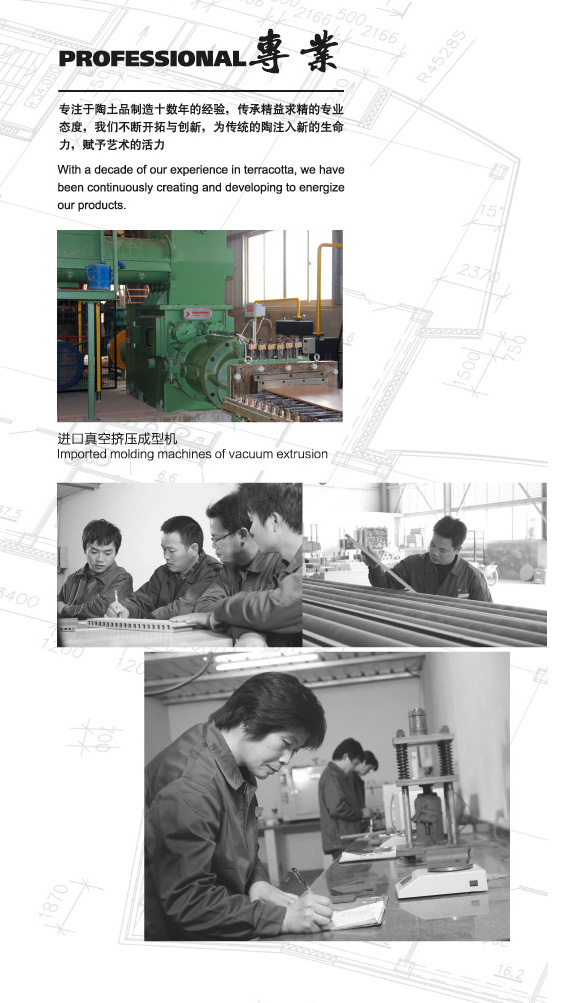

- Advanced Italian Equipment:

- Italian molding machines ensure stable extrusion processes, minimizing defects like cracks and uneven thickness, resulting in superior products.

- Innovative Drying and Firing Technology:

- A five-layer, 80-meter-high drying kiln offers ample time for semi-finished terracotta panels to optimize before entering the main kiln.

- China’s longest roller kiln at 260 meters, featuring 428 firing units, guarantees precision firing and high product quality.

- Automated Precision:

- Automatic cutting and edge grinding equipment reduce human error, improve efficiency, and maintain product consistency.

Massive Production Scale and Infrastructure

LOPO operates across two expansive industrial parks, covering over 540 hectares. The company’s terracotta panel factory alone spans an open stockyard of 80,000 square meters, backed by a vast indoor repository with a 150,000-ton capacity for semi-finished products. This infrastructure ensures that LOPO can meet growing global demand while maintaining product quality.

In addition to cutting-edge machinery, LOPO’s production facilities are designed for efficiency. The molding equipment, sourced from Italy’s renowned BONGIOUNNI, the extensive drying facilities, and the 260-meter roller kiln combine to create a smooth, uninterrupted production flow that optimizes both capacity and product excellence.

Conclusion

With its commitment to innovation, high-quality materials, and advanced production technologies, LOPO continues to be a leader in the terracotta and clay tile industry. The company’s massive production capabilities and cutting-edge equipment ensure that it can meet global demand while maintaining the highest standards of quality and sustainability.

By leveraging industry-leading technology and expansive raw material reserves, LOPO offers quick turnaround times and products that consistently exceed customer expectations.